Boller and Chivens developed a program for generating glass photo plates for large optical encoders.

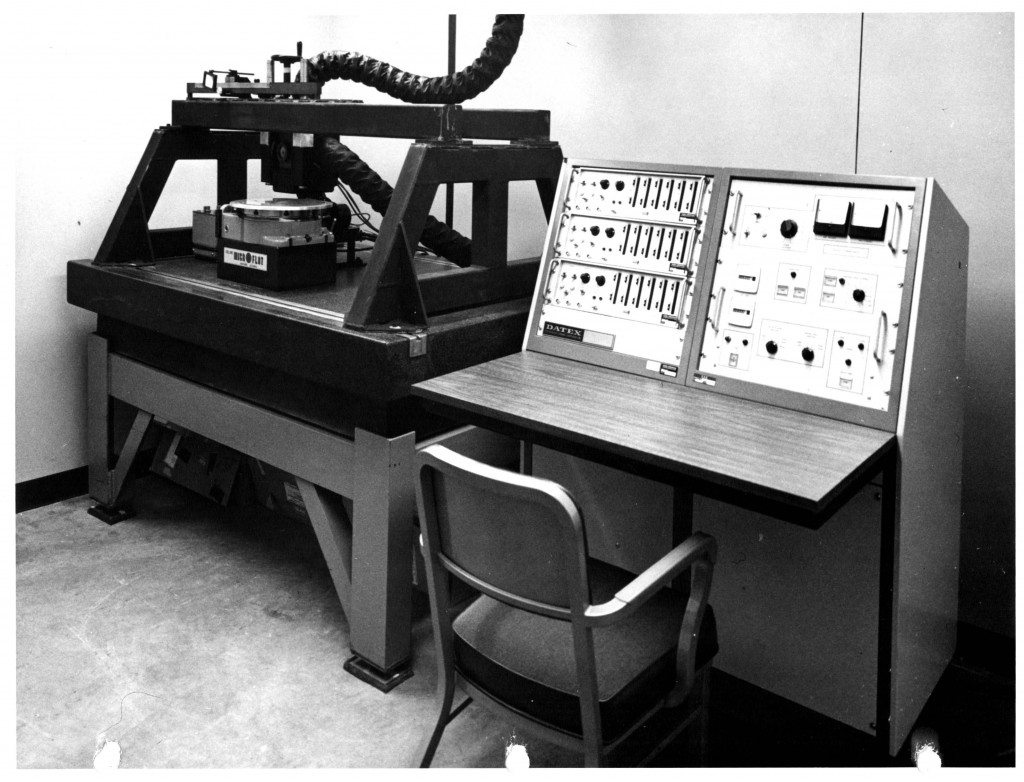

The assembly as built up :

1. Rubber Pads on Slab.

2. Steel Pads on Rubber Pads.

3. Heavy Steel Support Frame.

4. Thick Rubber Pads on frame.

5. Large Granite Surface Plate

6. Small Granite Surface Plate Bonded to Large Surface Plate

7. Precision Rotary Table operated by electronic Servo System from the control console.

8. Heavy support frame

9. Heavy cross beam

10. Optical Line Projection Assembly

11. Air Tubes scavenging projection lamp hot air away

The Operating Console.

The control panel would program the rotary table to index to many angular positions and produce.

short multiple radial lines at different radii.

With each revolution of the rotary table it was required to have absolute identical separation between

each of the hundreds of rotational lines that were being projected onto a glass photographic plate.

The temperature-controlled room was a positive clean–room environment.

Comments are closed.